Yamachiku

Yamachiku is a Kyushu-based manufacturer specializing in bamboo chopsticks. The region's warm climate provides ideal conditions for bamboo, with Kyushu accounting for about forty percent of Japan’s total forested area of bamboo. Since its founding in 1963, Yamachiku has remained committed to creating products that fully utilize this versatile material. While bamboo can be challenging to work with, the company’s deep knowledge and expertise have allowed it to craft durable, high-quality chopsticks with precision.

Yamachiku's Philosophy

Yamachiku makes chopsticks exclusively from pure, natural bamboo, carefully harvested from the mountains of Kumamoto and Fukuoka Prefectures. The difference is immediately noticeable, and many who use them find they prefer bamboo over other materials. Committed to quality, Yamachiku continues to craft chopsticks with the belief that they can make every meal more enjoyable.

Sustainability

Bamboo is one of the fastest-growing plants, with some species exceeding one meter per day under optimal conditions. In addition, bamboo forests can produce up to thirty percent more oxygen than many tree species while efficiently absorbing carbon dioxide and other greenhouse gases. However, if left unmanaged, certain species can spread aggressively and overtake surrounding forests.

Through the production of bamboo chopsticks, Yamachiku promotes sustainable bamboo management. Its goal is to cultivate bamboo responsibly, use it for chopsticks and other daily necessities, and support those involved in maintaining bamboo forests for future generations.

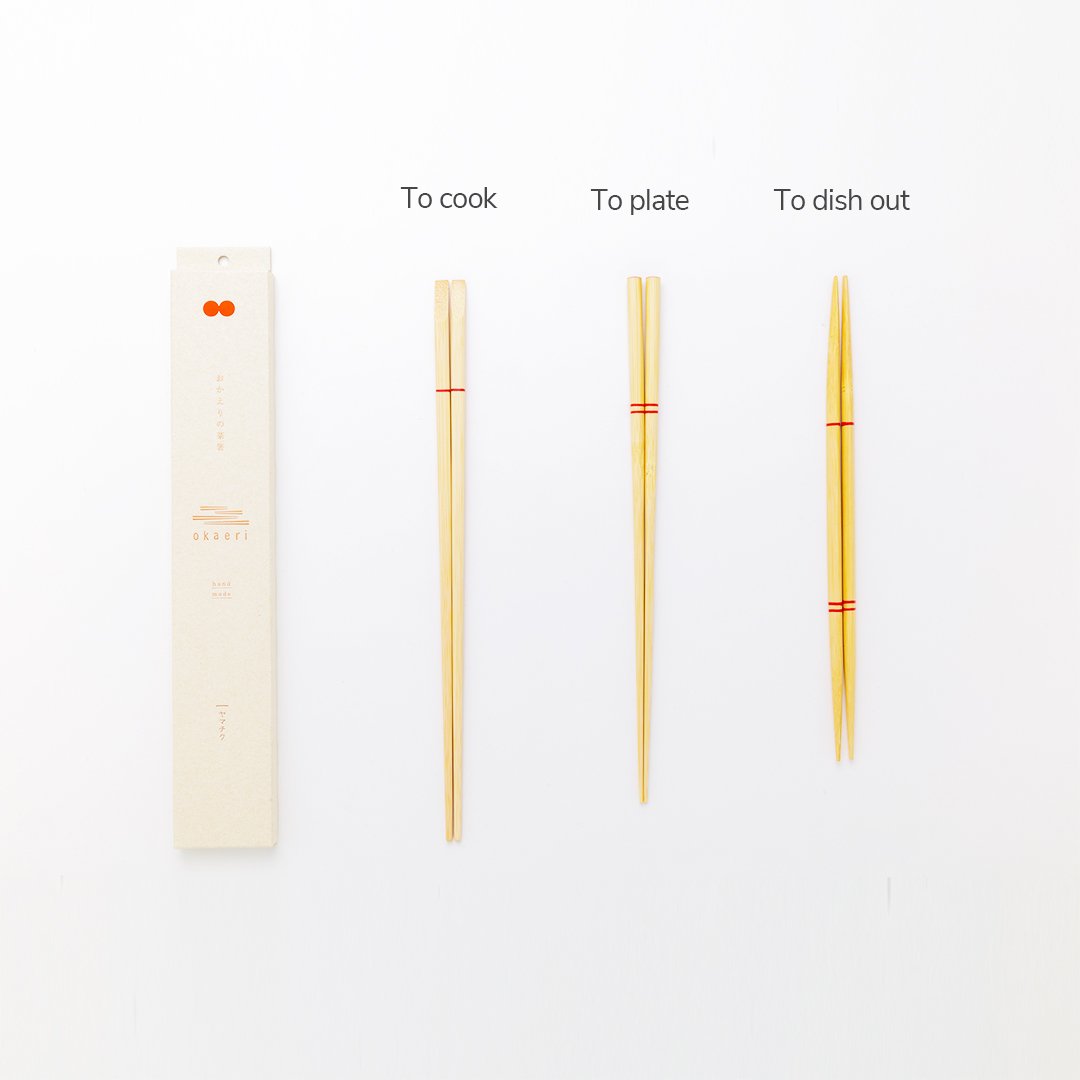

Bamboo chopsticks have been an indispensable part of Japanese dining for centuries. They are lightweight and flexible, making them ideal for picking up, separating, or stirring food. Their versatility allows for ease of use, enhancing the dining experience. Additionally, bamboo retains its strength even when shaped thin, allowing for the creation of delicate, beautifully crafted chopsticks that bring refinement to any table.

Inside Yamachiku’s Bamboo Chopstick Workshop in Kumamoto

Step inside the workshop at Yamachiku, a bamboo chopstick maker nestled in the mountains of Kumamoto, Kyushu. For over half a century, Yamachiku has specialized in crafting chopsticks from locally harvested bamboo—shaped by hand, finished with layers of lacquer, and known for their lightness, smooth grip, and timeless design.

During our visit, we spoke with the women who apply the lacquer by hand and asked them what makes Yamachiku special. From round to square, plain to colorful, each pair has its own unique charm—and it turns out, everyone has a favorite.

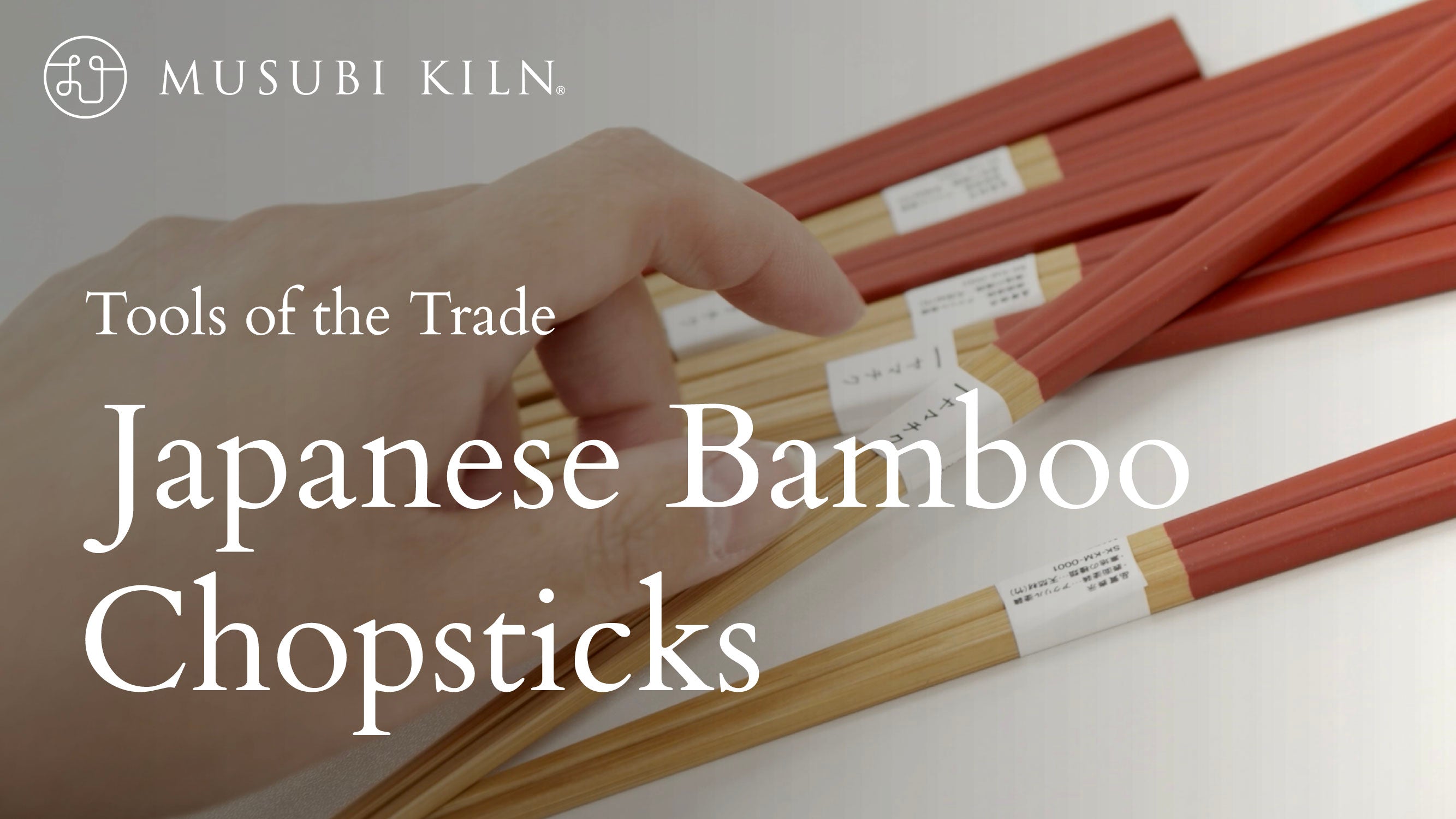

Tools of the Trade: How Bamboo Becomes Chopsticks

At Yamachiku, bamboo isn’t just a material—it’s a craft. Known for their dedication to handmade bamboo chopsticks, this workshop in Japan transforms raw, jointed stalks into elegant utensils through a careful blend of tradition and technique. From selecting the right bamboo to shaping each piece by hand, the process is a quiet but intricate art.

In this second look inside their workshop, we follow the transformation from heavy bamboo cylinders to refined chopsticks. It’s a story of patience, subtle adjustments, and craftsmanship passed down over time. Discover what makes bamboo chopsticks truly special—and why no two pairs are ever exactly the same.

Production Flow

Cutting

The chopsticks are made from natural bamboo, harvested in Fukuoka and Kumamoto Prefectures. Regular maintenance of the bamboo forests helps preserve the local ecosystem.

The harvested bamboo is supplied by trusted wholesalers, ensuring a stable and consistent source of natural materials. This allows for the steady production of bamboo chopsticks and other products. The bamboo is cut at the nodes to prepare it for drying.

Drying

The bamboo is dried to the appropriate size. Using a specialized kiln, its moisture content is reduced from approximately sixty percent to ten percent. It is then carbonized to prevent the growth of insects and fungi.

Processing

The bamboo is cut to uniform length and shaped into a stick. The outer bark is essential—removing too many fibers near the surface weakens the bamboo. To maintain its strength, it is processed using a specialized machine while carefully monitoring how much of the bark remains.

Finishing

To finish, paints and lacquers that meet Food Sanitation Law standards in Japan are applied. This not only enhances the appearance but also increases durability while preserving bamboo’s natural flexibility.

Inspection

Each chopstick is carefully inspected for stains, warping, or cracks. Even slight deviations—as small as 0.2 mm (7.9 mils) —are checked, and any piece that does not meet the standards is removed. This rigorous process ensures the consistent quality that defines Yamachiku’s craftsmanship.

Origin & Other Makers

Filters