Lacado de madera japonés

Lacado Yamanaka

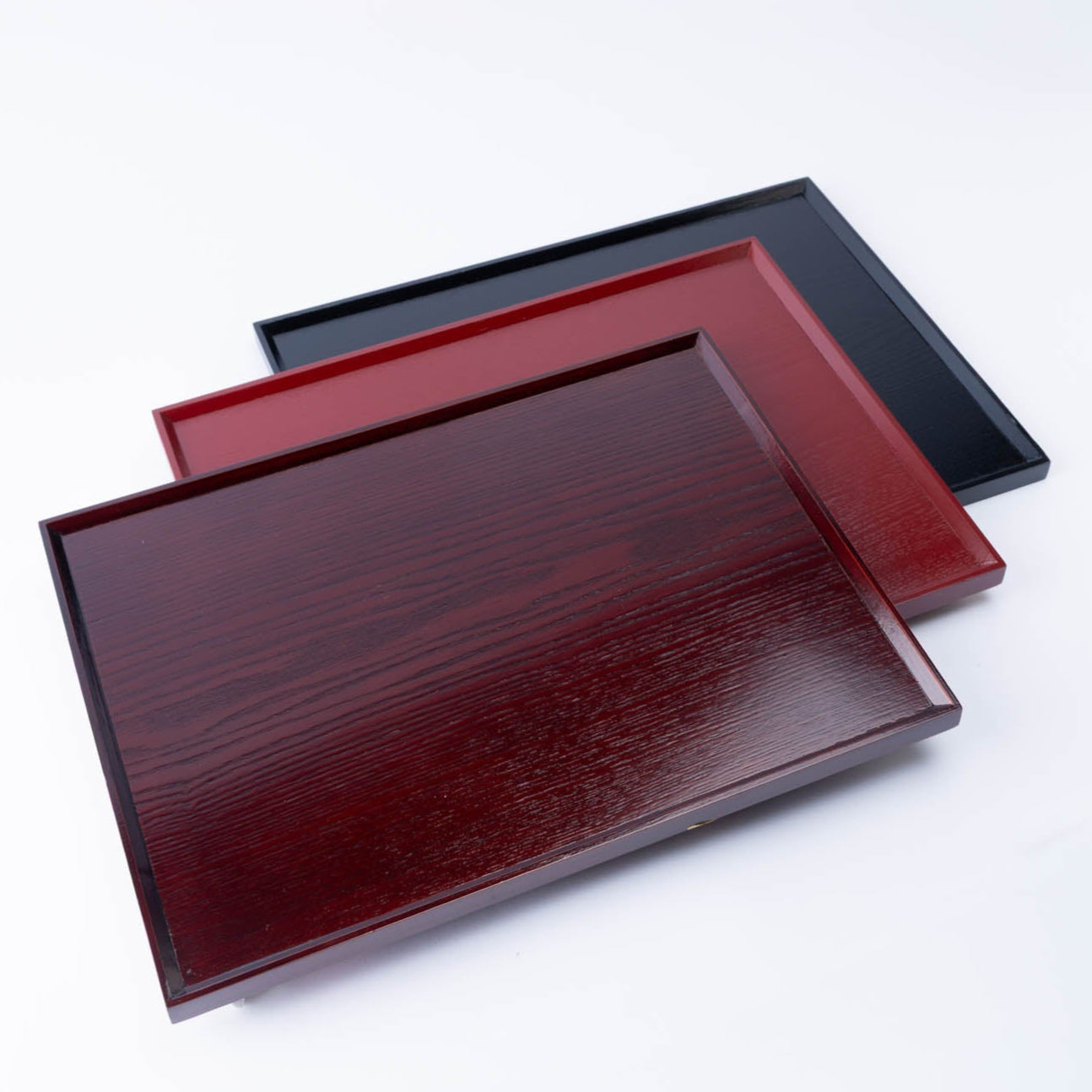

Lacado Yamanaka, también conocido como Yamanaka shikkiEs un tipo de laca producida en el distrito Yamanaka Onsen de Kaga, prefectura de Ishikawa. Esta laca es única porque combina la elegancia natural de la veta de la madera con la elegancia... maki-e Técnica que consiste en espolvorear oro, plata u otro polvo de color sobre una pintura de laca.

Con su hermosa textura de madera, la delicada y robusta laca de Yamanaka incorpora un sentido moderno de diseño al tiempo que hereda una tradición que ha durado 400 años.

La laca Yamanaka se elabora en la prefectura de Ishikawa, una de las principales zonas de producción de laca japonesa. Se llama Yamanaka porque se elabora en la zona de aguas termales de Yamanaka Onsen, en la ciudad de Kaga. En la prefectura de Ishikawa, existen otras dos zonas de producción de laca japonesa: Wajima y Kanazawa. Entre ellas, Yamanaka es conocida como la "Yamanaka de la madera" y es el mejor lugar de Japón en cuanto a técnicas de ebanistería.

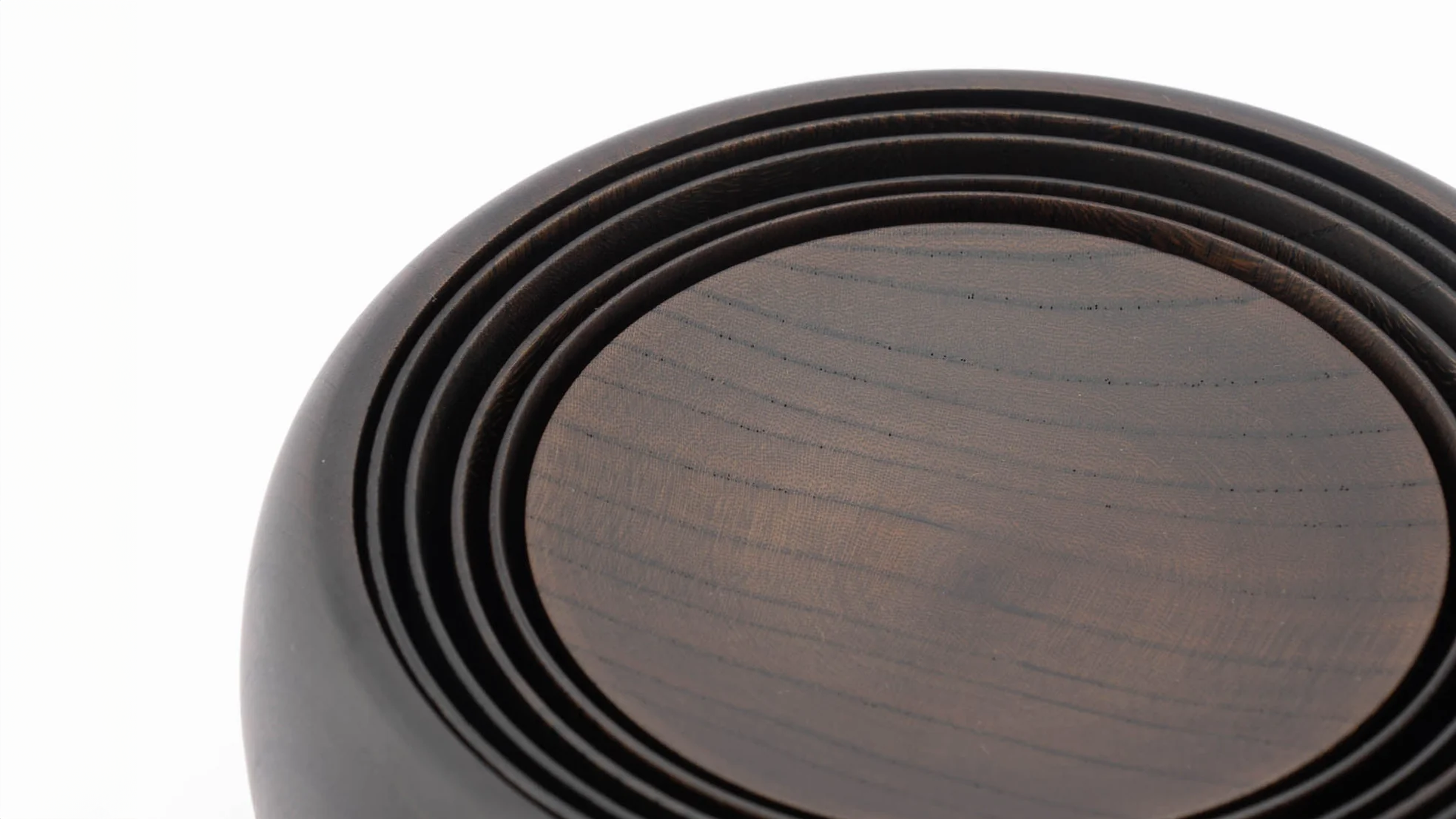

La característica principal de la laca Yamanaka es el procesamiento de la veta de la madera. Al ahuecar la madera de forma que la veta discurra verticalmente, la laca Yamanaka produce vasijas robustas, delgadas y delicadas que no se deforman fácilmente con el secado.

La laca Yamanaka, también conocida como "Yamanaka-Nuri" en la antigüedad, nació hace unos 400 años en el período Azuchi-Momoyama (1568-1600).

Se dice que se originó cuando un grupo de artesanos ambulantes llamados "Kiji-Shi", que se ganaban la vida fabricando vasijas de madera con un torno de madera, se asentó en un lugar llamado Masago, río arriba de Yamanaka Onsen. Durante el período Edo (1603-1868), se introdujeron técnicas de lacado y maki-e de Aizu, Kioto y Kanazawa, que evolucionaron hasta convertirse en la laca de Yamanaka, y se inventaron diversas técnicas. Posteriormente, alrededor del período Meiji (1868-1912), se formó el estilo actual de la laca de Yamanaka.

En 1913, gracias a la inauguración del ferrocarril, se facilitó el acceso a materias primas para la laca y comenzó la producción en masa de productos económicos. Sin embargo, para el Período Taisho (1912-1926), la laca Yamanaka se había convertido en la laca oficial de la Corte Imperial Japonesa. En 1981, la laca Yamanaka se convirtió en el mayor productor de laca de Japón.

Artesanía de laca de madera de Yamanaka

Se dice que las técnicas de carpintería de Yamanaka son las mejores de Japón. ¿Alguna vez has visto piezas de madera tan finas que se pueden ver a través de la luz? Las delicadas piezas de madera son posibles gracias a la gran habilidad y dedicación de los artesanos, quienes empiezan forjando sus propias herramientas en acero.

Desde su fundación, la ebanistería de Yamanaka Lacquerware se ha caracterizado por la técnica del pulido de la madera en un torno. Basada en la técnica "Kiji-Biki", que consiste en tallar finas líneas concéntricas en un torno, Yamanaka Lacquerware presenta diversos diseños tallados, incluyendo el "Sensuji", un diseño típico de Yamanaka Lacquerware con un patrón de rayas verticales.

Procesos de elaboración de la laca de Yamanaka

Además, la laca de Yamanaka se elabora mediante una división del trabajo entre artesanos, comenzando por los Kiji-Shi (ebanistas). Además, están los Shitaji-Shi (artesanos de base), que elaboran la base de la laca; los Nuri-Shi (lacadores), que aplican y terminan la laca; y los Makie-Shi (lacadores de maki-e), que se encargan del maki-e. La laca de Yamanaka, caracterizada por la belleza natural de la veta de la madera y la elegancia del maki-e, es elaborada por estos artesanos.

Kiji-Shi Woodcarvers

Tallador de madera "Kiji-Shi"

Los talladores de madera son conocidos como "Kiji-Shi" en japonés. Utilizan madera de zelkova, castaño de Indias, cerezo, castaño, etc., de buena calidad, que se corta a la forma de la vasija que se va a fabricar, se seca y luego se ahueca en un torno con un cepillo o una cuchilla.

La técnica tradicional de lacado Yamanaka llamada "Kasyoku-Biki", en la que la superficie de la madera se decora con el giro del torno, otorga belleza y evita el deslizamiento, y es una de las características del lacado Yamanaka.

Laca "Nuri-Shi"

Una vez preparada la base, es el momento de que el lacador, "Nuri-Shi", aplique la laca japonesa. Este proceso se realiza con un pincel y requiere controlar la humedad para que la laca se endurezca y una concentración total para evitar que el polvo y la suciedad se adhieran a la superficie.

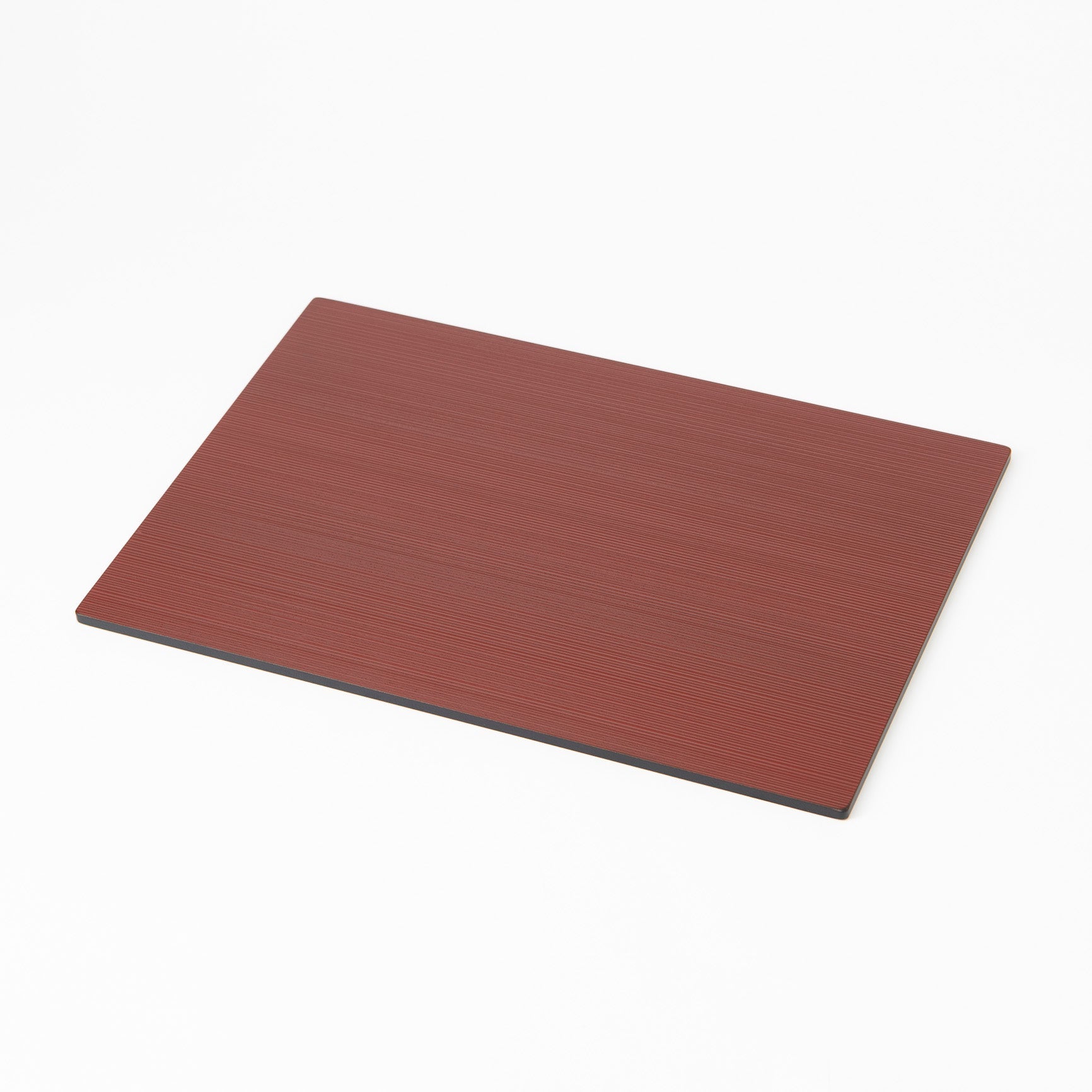

Una de las técnicas denominada "Fuki-urushi" es una forma de aplicar laca que aprovecha al máximo la belleza de la veta de la madera, en la que el proceso de aplicar y limpiar la laca transparente se repite muchas veces para permitir que la laca penetre en la veta de la madera.

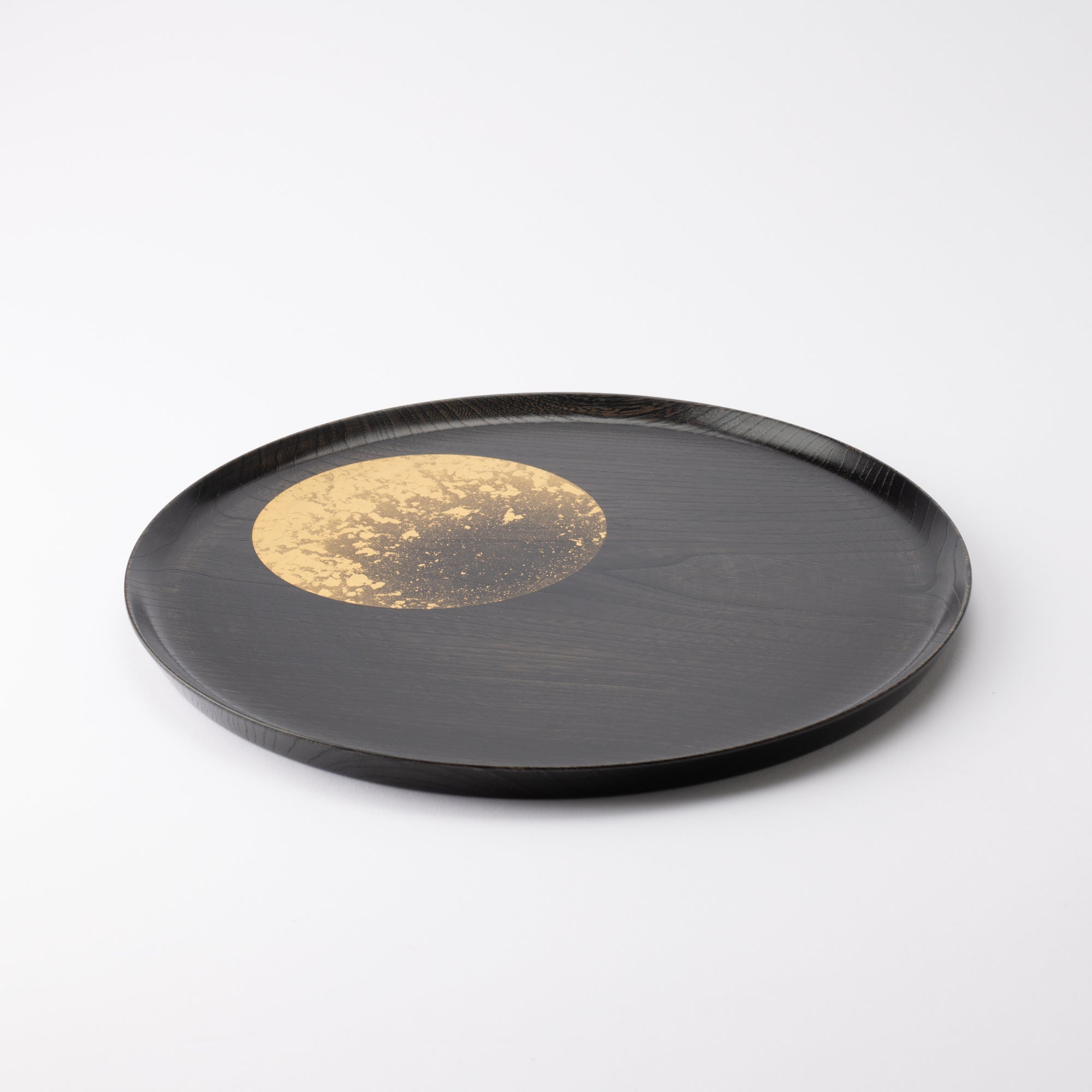

Artista de Maki-e

El hermoso maki-e es obra de un artesano especializado, "Maki-e Shi". Primero, se copia un boceto sobre la superficie de la pieza terminada de laca japonesa y se dibujan patrones y letras con laca japonesa. Luego, mientras la laca se endurece, se espolvorea metal y polvos de colores como oro y plata sobre la superficie. Después, se recubre con laca japonesa transparente y se pule cuidadosamente.

Hay una variedad de técnicas Maki-e en Japón, y la laca Yamanaka es famosa por su técnica "Taka Maki-e", que da un efecto tridimensional.

Fotos de Yamanaka Japón

Creadores

Artículos relacionados

Filtros