17 April 2024

The Birth of the Moist Series: Inside Hataman Touen's Workshop

In the gallery of Hataman Touen, we were enveloped in awe as we witnessed an unparalleled combination of technical mastery and elegant designs, leading us further into the heart of their operations.

The workshop we entered could best be described as a pinnacle of modern craftsmanship: every tool and piece of equipment were meticulously organized and well-maintained, with the floors spotless and pristine. Through the windows, the majestic mountains of Okawachiyama offered a serene backdrop.

This workshop was set apart by the gentle hum of pop music in the background, creating a rhythm that was mirrored in the smooth and unhesitating movements of the artisans' hands. This place was the very epitome of Hataman Touen's fusion of cleanliness and contemporary elegance.

We invite you to explore this workshop and its unique atmosphere for yourself.

Contents

- Overglaze Enamels

- Underglaze Painting

- The Kiln Area

- The Making of the Moist Series

Overglaze Enamels

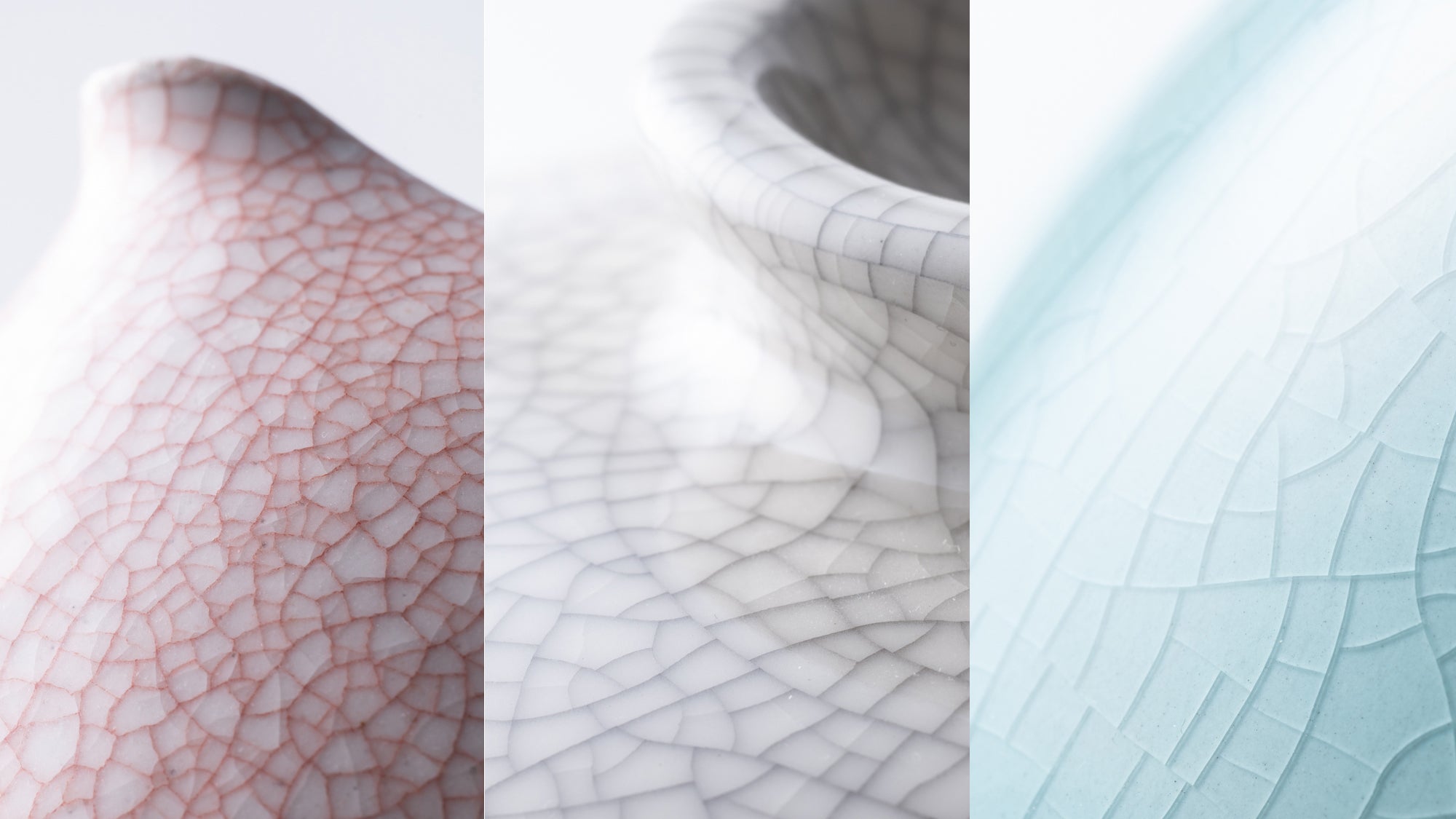

Our journey began in the overglaze enamels section, where three skilled painters meticulously applied their craft. This technique involves the application of overglaze enamels onto already glazed and fired pottery. The efficiency and speed of their work were remarkable — each movement was precise, resulting in bright, vibrant lines swiftly adorning the plates.

Hataishi Hiroaki, who guided us through the workshop, informed us that the enamels are specially commissioned from a traditional supplier in Arita, ensuring a perfect harmony of colors. The art of line drawing requires a high degree of accuracy, while the use of gradients and colors necessitates a refined sense of style. The various brushes used, sourced from a specialist in Kumano Town, Hiroshima, are carefully selected for each specific painting task.

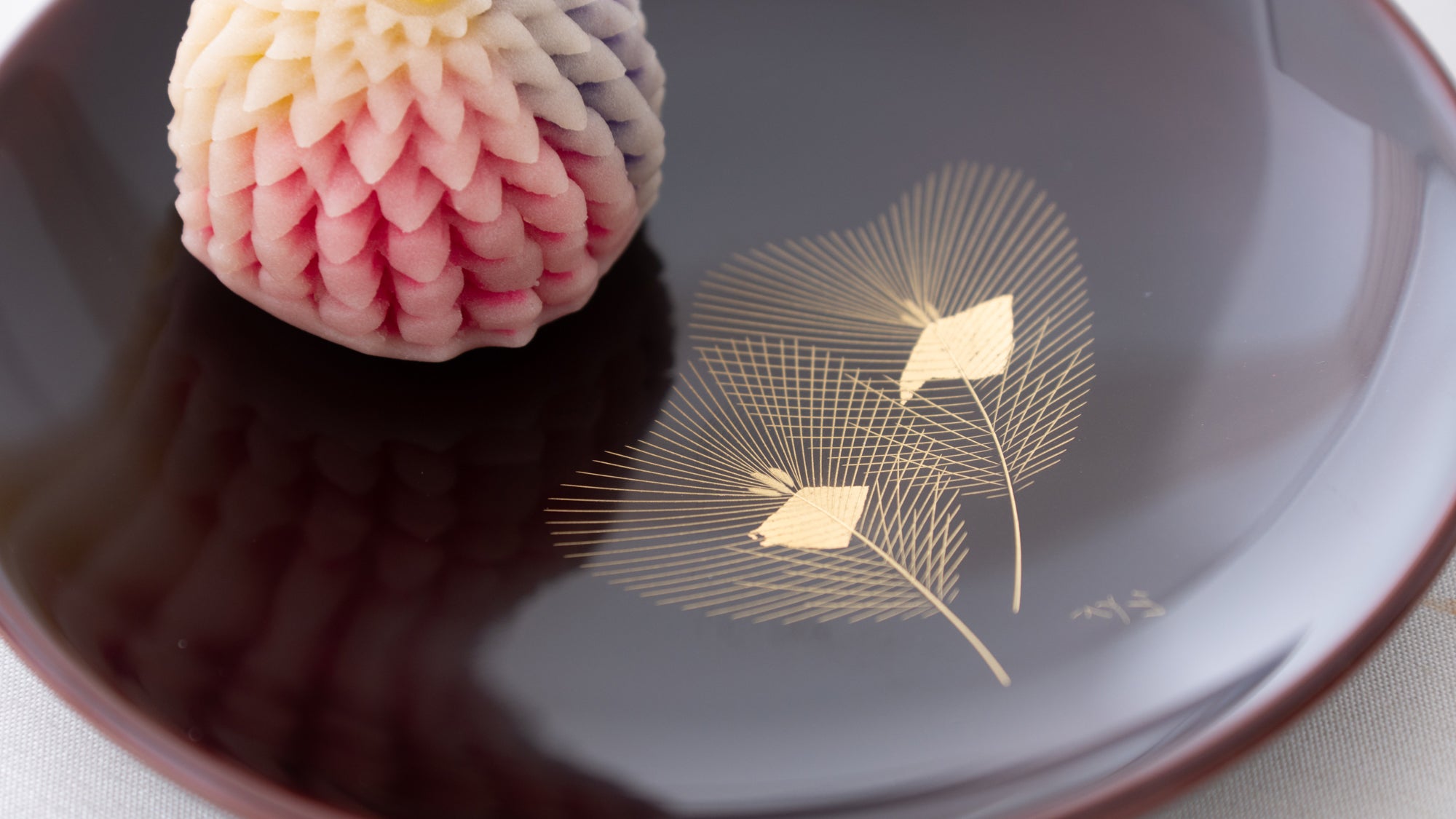

Upon completion, the uniformity of the hand-painted designs on the items was astounding, especially considering that they were all crafted by hand. This consistency is a testament to the artisans' years of experience, allowing for the creation of delicate yet striking Iro-Nabeshima decorations.

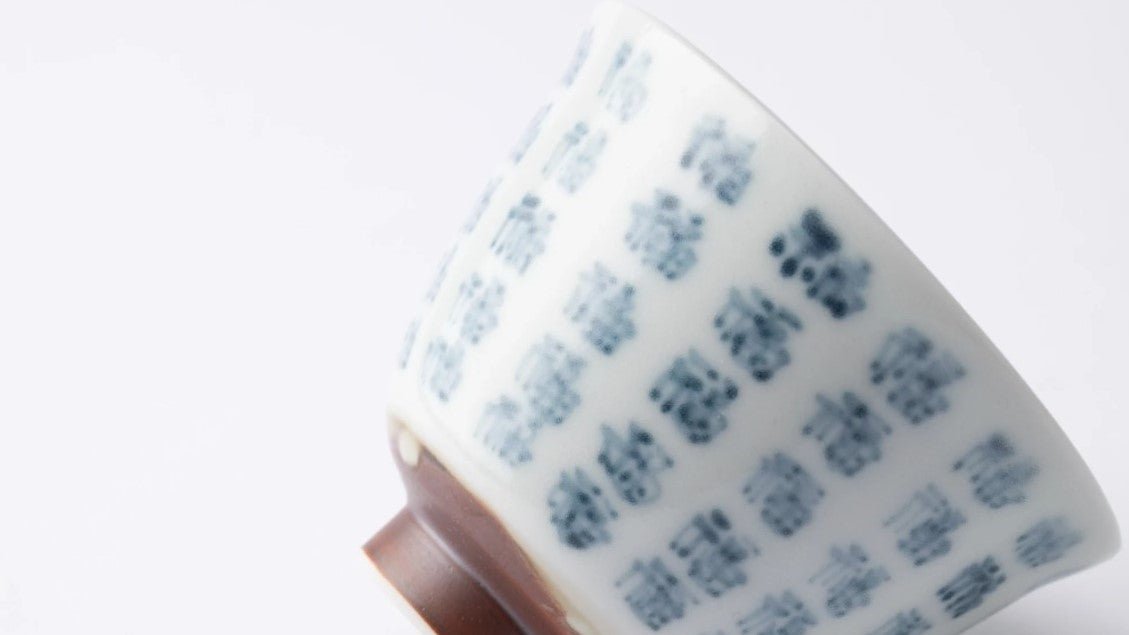

Underglaze Painting

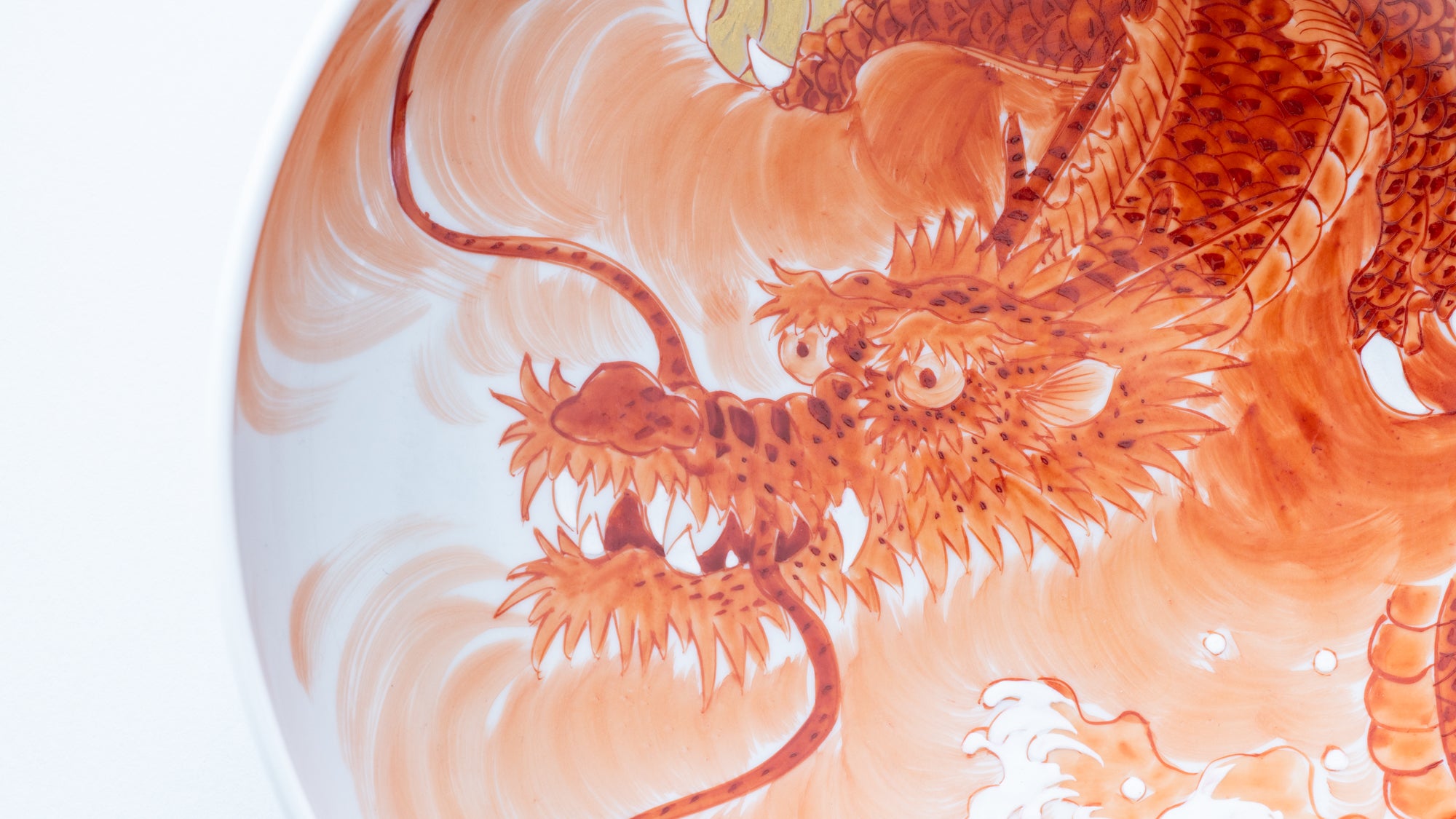

We then moved to the underglaze painting area, typically staffed by four to five artisans. Here, the artists paint on bisque-fired pottery before it undergoes glaze firing, mainly using a cobalt-based pigment called gosu.

The delicate line work in this section is handled by artisans of the highest skill level. For example, one artist specializes exclusively in the traditional Iro-Nabeshima design, and possesses the unique qualification of traditional crasftsperson of Imari-Arita ceramics.

Hataishi explained that while the designs often draw inspiration from traditional Nabeshima patterns, many are also developed in-house at Hataman Touen. These designs start from basic sketches and are often refined in collaboration with the artisans, some of whom also contribute their own ideas.

Owing to the intricate nature of the painting, the pottery shapes produced in large quantities are kept simple and functional, designed to avoid damage during firing and to ensure ease of use. Recently, there has been an increasing demand for items that are stackable and easy to store, a trend driven by customer feedback.

The Kiln Area

Our descent into the kiln area revealed a space equipped with the latest kilns, set against a backdrop of high ceilings — a truly awe-inspiring sight. "When I was a kid, it wasn't this clean," Hataishi reminisced, drawing a contrast with the typical town factories of the past, marked by soot-covered workers. This transformation has markedly increased efficiency.

Here, the bisque-fired pottery awaited firing at temperatures between 800-900 °C (1472-1652 °F), neatly arranged and ready for the next phase.

The main kiln, with a capacity large enough to easily fit several people, operates weekly, primarily over the weekends. Each firing session lasts about eighteen hours at approximately 1300 °C (2372 °F), nearly a full day. The resulting high-temperature reduction firing gives the porcelain a translucent, paper-thin quality, further accentuating its whiteness. While the kiln provides warmth in winter, it becomes unbearably hot in summer, overwhelming even the air conditioning.

The kiln dedicated to firing pieces after underglaze painting, located near the entrance, operates at around 800-900 °C (1472-1652 °F) for about eight hours, and is almost constantly in use.

The Making of the Moist Series

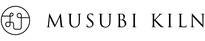

Lastly, we had the opportunity to delve into the creation of the popular Moist series. Hataishi showed us a piece in its pre-sandblasting stage — a process where glass powder is blasted onto the surface using a compressor, removing the gloss from the celadon glaze. The celadon glazing is performed here, while the sandblasting is outsourced or done in-house at a different location.

"Matte celadon is quite a rarity," Hataishi noted. "Achieving this finish requires the original celadon to be fired perfectly."

The Moist Series, known for its distinctive charm — akin to frosted glass and imbued with a sense of transparency and freshness — has become a flagship product for Hataman Touen. Interestingly, the most sought-after item at MUSUBI KILN is the crane-motif small box, celebrated for its charming and elegant design.

Visiting the Hataman Touen workshop, it became clear once more how the harmony between traditional craftsmanship and modern efficiency culminates in the creation of unique pieces like the Moist series. This workshop tour, though reservation-based, is complimentary on weekdays. It's a rare opportunity to experience the inner workings of Nabeshima porcelain making — an opportunity not to be missed for those who can partake.

View Hataman Touen Collection