Interview With An Artist: Ritsuzan Tomita - Chinkin

Written by Team MUSUBI

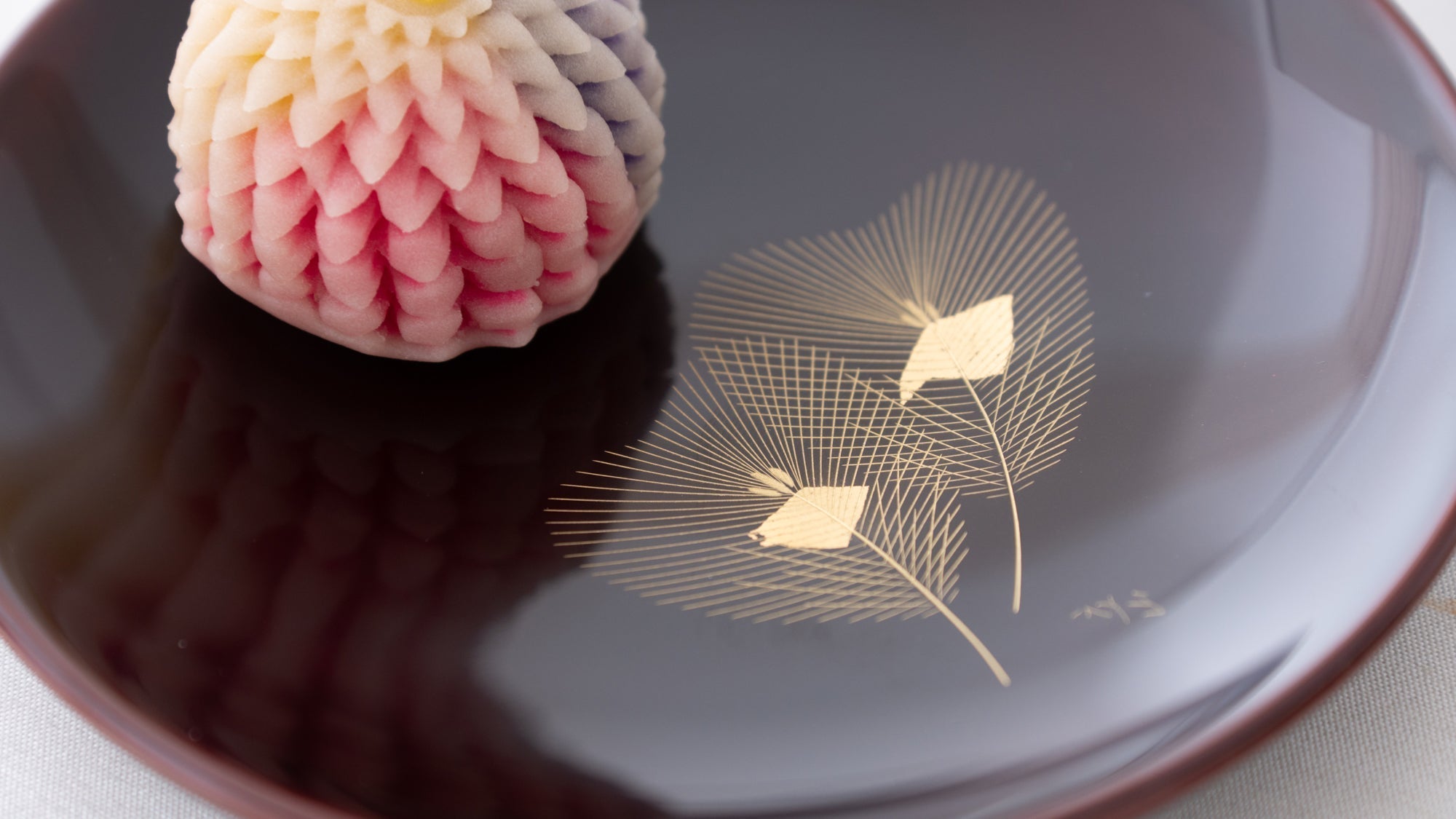

"Chinkin" is a technique that elegantly decorates the lustrous surface of lacquerware with gold. Chinkin means "sunken gold" in Japanese as gold leaves and powder are "sunken" into intricately carved designs on a lacquerware surface.

The origin of Chinkin dates back to the Song dynasty (960-1279) in China. Pieces decorated with gold from China came to Japan around the 14th century and the technique of Chinkin was developed during the Edo period.

tables of contents

The Chinkin Technique

First, we asked Ritsuzan how the grooves were carved out without damaging the lacquer coat.

"For Chinkin, we only carve the top thin coat of the lacquer. If you carve too deep, you can damage the lacquer coating and cause exposure of the middle coat and even the wooden base of the item. So the groove is not as deep as one might expect."

He went on to explain how the grooves are so thinly carved out.

"In order to carve a long, thin line on a well-dried lacquer surface, you need to 'scratch' the surface in one smooth motion. When this is done perfectly, you will hear an almost 'hissing' sound made by a cat and will produce shavings as thin as hair.

But when a product's lacquer coat is freshly painted, and there isn’t enough time to let the coat dry completely due to tight scheduling, it’s quite difficult to make the smooth and thin incisions. But these are challenges that a craftsman must overcome."

Okime (Pattern sketches)

"The base sketched designs of Chinkin are called 'Okime.' Designs on the Okime are traced onto thin sheets of paper and mixed with lacquer color powder. Then the design is traced from the back and transferred onto the surface of an item. On this thin paper, notes regarding carving techniques and the color of the metal powder are written by pencil."

Tools

"The Chinkin knives shown in the photo are only a small part of my whole set. The fifth one from the right is the one I often use. I carefully choose the chisel with the appropriate thickness for each item I decorate, and then sharpen it according to the motif and technique. The short chisels are the ones that have been sharpened and polished over the many years of use."

He explained the delicate touch needed to sharpen the chisels.

"The delicate and fine adjustments of chisels are something that only a craftsman can feel, it’s difficult to describe in words. When I was apprenticing at Wajima, I was never taught how to take care of my tools by my master or by the other senior apprentices. Even after returning to Echizen, my father didn't teach me on how to sharpen tools. You need to rely on your own sense of touch, and adjust the sharpness and smoothness of the Chinkin chisels like they were your own fingertips."

"Before I start working, I first sharpen my tools. But they do need to be repeatedly sharpened during the process of carving out multiple designs. If I were to work on a Jubako bento box, I would finish one set, sharpen my chisels and then carve several more sets."

Preserving Tradition

"Most of the sketches we use were passed down from my father and are organized and kept in drawers. We've kept the sketches that haven't actually been used to make a product as well.

We organize the sketches according to each customer. And the sketches for specially popular items for each customer are kept in a different drawer.

The sketched designed for popular items are used repeatedly. We replace them with newly drawn sketches once they are worn out after being traced for many times."

The Future of Chinkin

Ritsuzan follows the work ethics passed down from his father. He spoke about his father's teachings and his own thoughts about how he hopes to develop the technique of Chinkin in the future.

"My father taught me the importance of continuing to do what is expected of a dedicated craftsman: to promptly create beautiful products with care. I also learned the significance of taking on new challenges. Through his works exhibited at Nitten, the most prestigious combined art work exhibition in Japan,

my father always strived to try new ideas, and applied this 'challenging spirit' to develop new products."

The present Ritsuzan has also exhibited multiple works at Nitten and has received multiple awards for his craft.

"We continue to follow this path as we have used the Chinkin techniques on different materials such as ceramics and acrylics in addition to lacquerware. We received an award for ceramic items decorated with our Chinkin technique, and acrylic partitions beautifully crafted with our Chinkin designs were introduced by the local media as a new way of celebrating Japanese aesthetics."

The exquisite gold designs created by Chinkin on lacquerware accentuates the elegance of lacquer and the luxuriousness of gold. Chinkin was developed as a decorative technique for lacquerware, but continues to evolve as a technique that can be applied to other materials and items other than tableware. Ritsuzan's dedication to his craft and innovative ideas for new products give us a bright outlook for the future path of Chinkin.

Echizen Lacquerware Ritsuzan Tomita

Ritsuzan Tomita is a renowned and an award-winning "Chinkin" craftsman. Chinkin is a traditional technique where thin grooves made on lacquerware surfaces are filled with gold leaves and powder. He succeeded his father's name of Ritsuzan in 2017 and the Chinkin Tomita Ritsuzan Workshop located in Fukui Prefecture. He did his apprenticeship of Chinkin in Wajima, and then studied under his father, the first generation Ritsuzan Tomita who was an award-winning master craftsman of Chinkin.

2 comments

@Svetlana How wonderful that your new vase is Wajima-Nuri with chinkin! The technique is breathtaking and your vase must be gorgeous, quietly. We appreciate you for reading our journal and enjoying the art of chinkin!

Team Musubi

I have just bought a vase with chinkin technique and started reading about it. Google identified my vase as Wajima-nuri. I am glad to see this information to know more.

Svetlana

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.