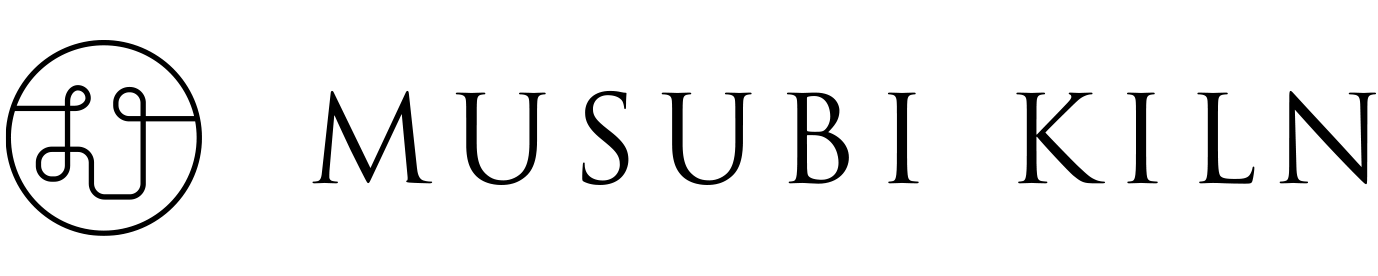

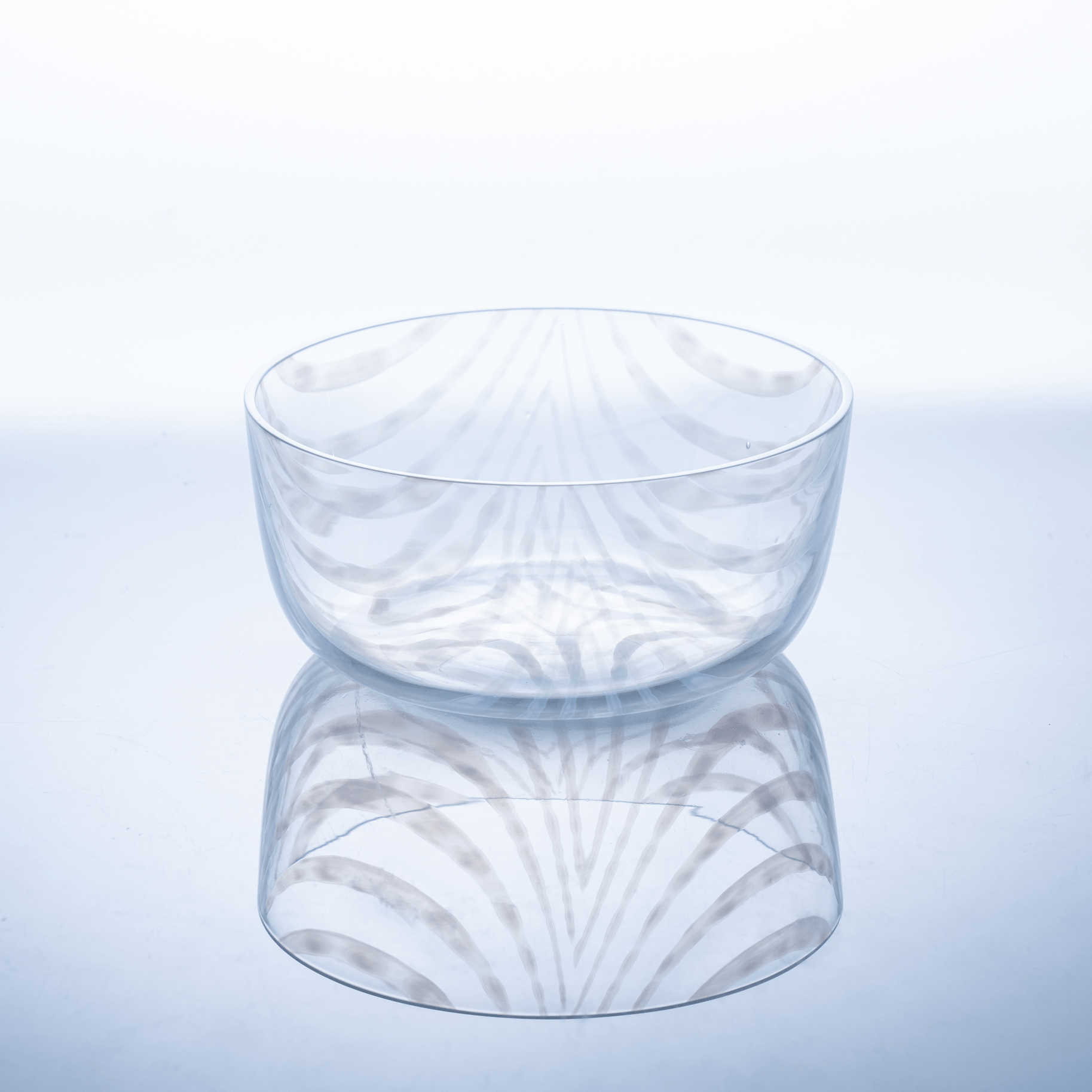

Hirota Glass Taisho Roman

In the 1980s, Hirota Glass, an Edo glassmaker, designed the Taisho Roman series. The "milky white glass" manufacturing method, popular during the Meiji (1868 CE–1912 CE) and Taisho (1912 CE–1926 CE) eras, was revived for this series through a process of trial and error.

Today, with the exception of antique stores, it is rare to encounter glassware that employs this technique.

The Art of Milky-White Glass

The milky-white patterns are not painted on the glass but are created by exposing the glass to rapid changes in temperature during the molding process, using a material that contains a natural ingredient called bone ash.

Enjoy the transient yet stunning opalescent hues, crafted by the artisan's precise temperature control.

The base is made by wrapping milky-white glass around clear glass.

The base is blown into an uneven mold to create an uneven glass bulb. Patterns begin to appear faintly.

After the bulb cools down, it is reheated in the kiln. Patterns start to emerge.

The glass is then blown into another mold to be formed into glass cups or other shapes. The surface becomes smooth, and the patterns appear with the change in temperature.

Unnecessary parts are cut off, seared and smoothed, and then allowed to cool slowly over a period of two hours, completing the process.

Filters