Japanese Wooden Lacquerware

Yamanaka Lacquerware

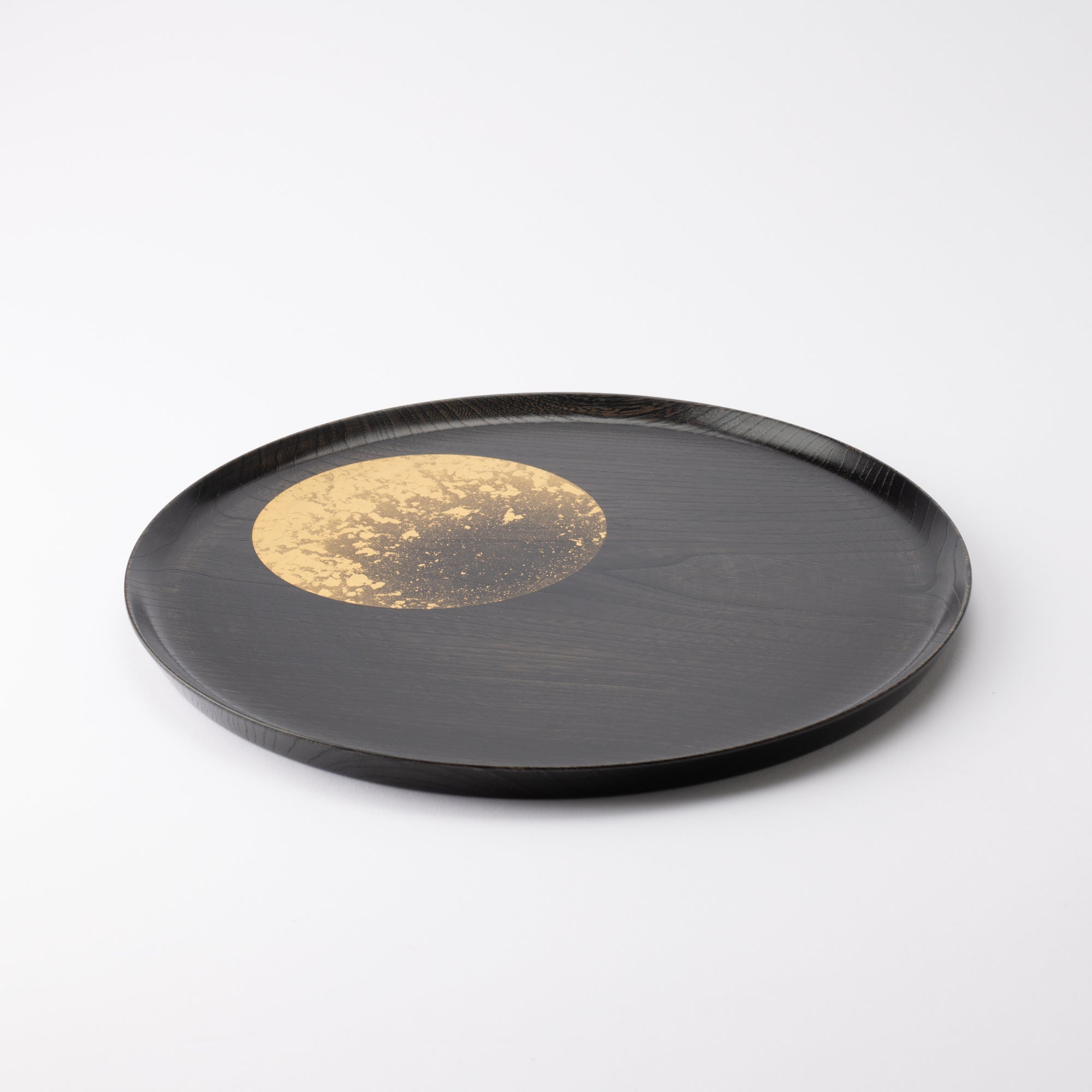

Yamanaka lacquerware, also known as Yamanaka Shikki, is a kind of lacquerware produced in the Yamanaka Onsen district of Kaga, Ishikawa Prefecture. This lacquerware is unique in that it blends wood grain's natural elegance with the elegant maki-e technique of sprinkling gold, silver, or other colored powder onto a lacquer painting.

With its beautiful wood texture, delicate and robust Yamanaka lacquerware incorporates a modern sense of design while inheriting a tradition that has lasted for 400 years.

Yamanaka Lacquerware is made in Ishikawa Prefecture, one of the leading production areas of Japanese lacquerware, and is named after its place of origin, the Yamanaka Onsen (hot springs) area of Kaga City. Ishikawa Prefecture contains two other Japanese Lacquerware production areas, Wajima and Kanazawa. Yamanaka is considered the best in Japan when it comes to woodworking techniques.

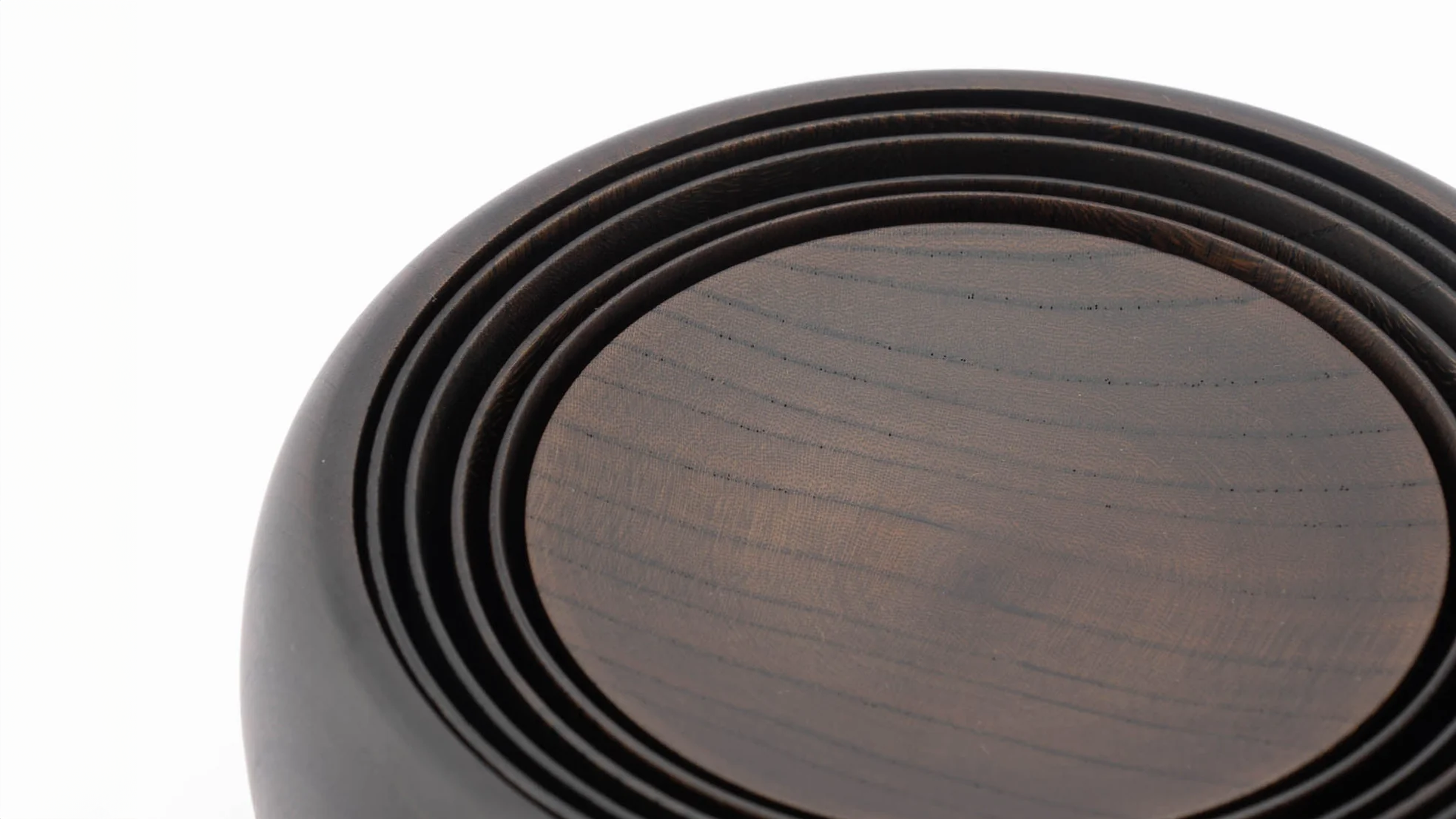

The distinguishing characteristic of Yamanaka Lacquerware is wood grain processing. The wood is hollowed out in such a way that the grain runs vertically, producing robust, thin, and delicately formed vessels that are not easily distorted by drying.

Yamanaka lacquerware is also known as Yamanaka nuri. It was born about 400 years ago in the Azuchi-Momoyama period (1573–1603 CE).

It is said to have originated when a group of wandering craftsmen called kiji-shi, who made a living by making wooden vessels using a wooden wheel, settled in Masago, upstream from Yamanaka Onsen. In the Edo period (1603–1868 CE), lacquering and maki-e techniques were introduced from Aizu, Kyoto, and Kanazawa and developed into Yamanaka Lacquerware, and various techniques were invented. Yamanaka lacquerware’s current style developed around the Meiji period (1868–1912 CE).

During the Taisho period (1912–1926 CE), especially after the opening of the railroad in 1913, it became easier to procure raw materials, and the production of inexpensive mass-market wares began. Yet by the same period, Yamanaka lacquerware had already been designated as the official lacquerware of the Japanese Imperial Court. In 1981, Yamanaka became the largest producer of lacquerware in Japan.

Yamanaka's Wooden Lacquerware Craft

Yamanaka's woodworking techniques are said to be the best in Japan. Have you ever seen woodcraft so thin you could see light through it? Such delicate wooden vessels are made possible by the high level of skill and dedication to sharpness of the craftspeople, who start from forging their own tools from steel.

Since its founding, Yamanaka Lacquerware's woodworking has been characterized by the technique of grinding wood on a lathe. Based on the kiji-biki technique, which involves carving fine concentric lines when carving on a lathe, Yamanaka lacquerware has various types of carved designs, including sensuji, a typical Yamanaka lacquerware design of a striped pattern carved vertically.

Kiji-Shi Woodcarvers

Woodcarvers are known as kiji-shi in Japanese. Using good quality domestic zelkova, horse chestnut, cherry, chestnut, and other woods, the wood is cut to fit the shape of the vessel to be made, dried, and then hollowed out using a plane or knife while being turned on a lathe.

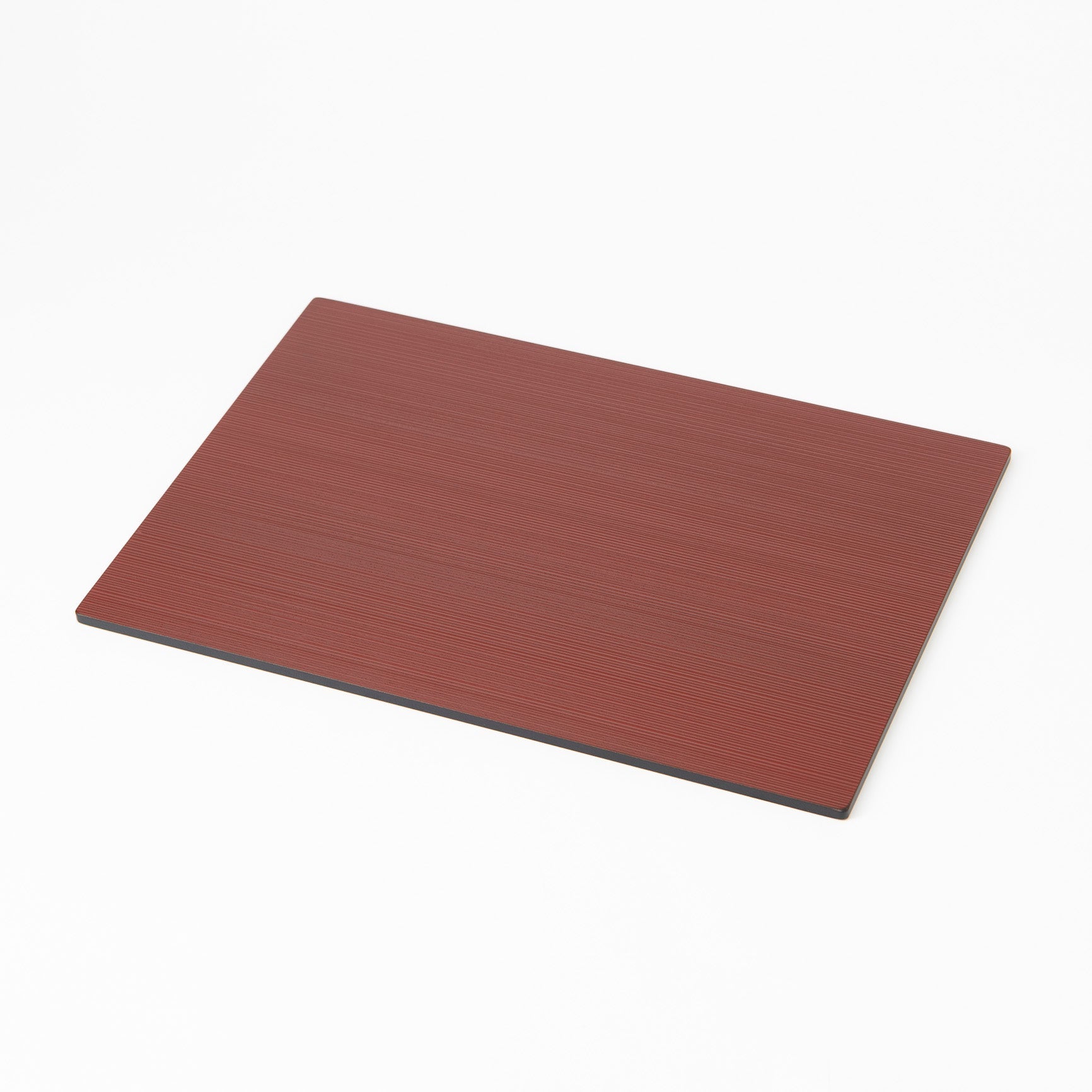

The traditional Yamanaka lacquerware technique of kashoku-biki, in which the surface of the wood is decorated by the spinning of the lathe, gives beauty and prevents slippage, and is one of the defining characteristics of Yamanaka lacquerware.

Nuri-Shi Lacquerers

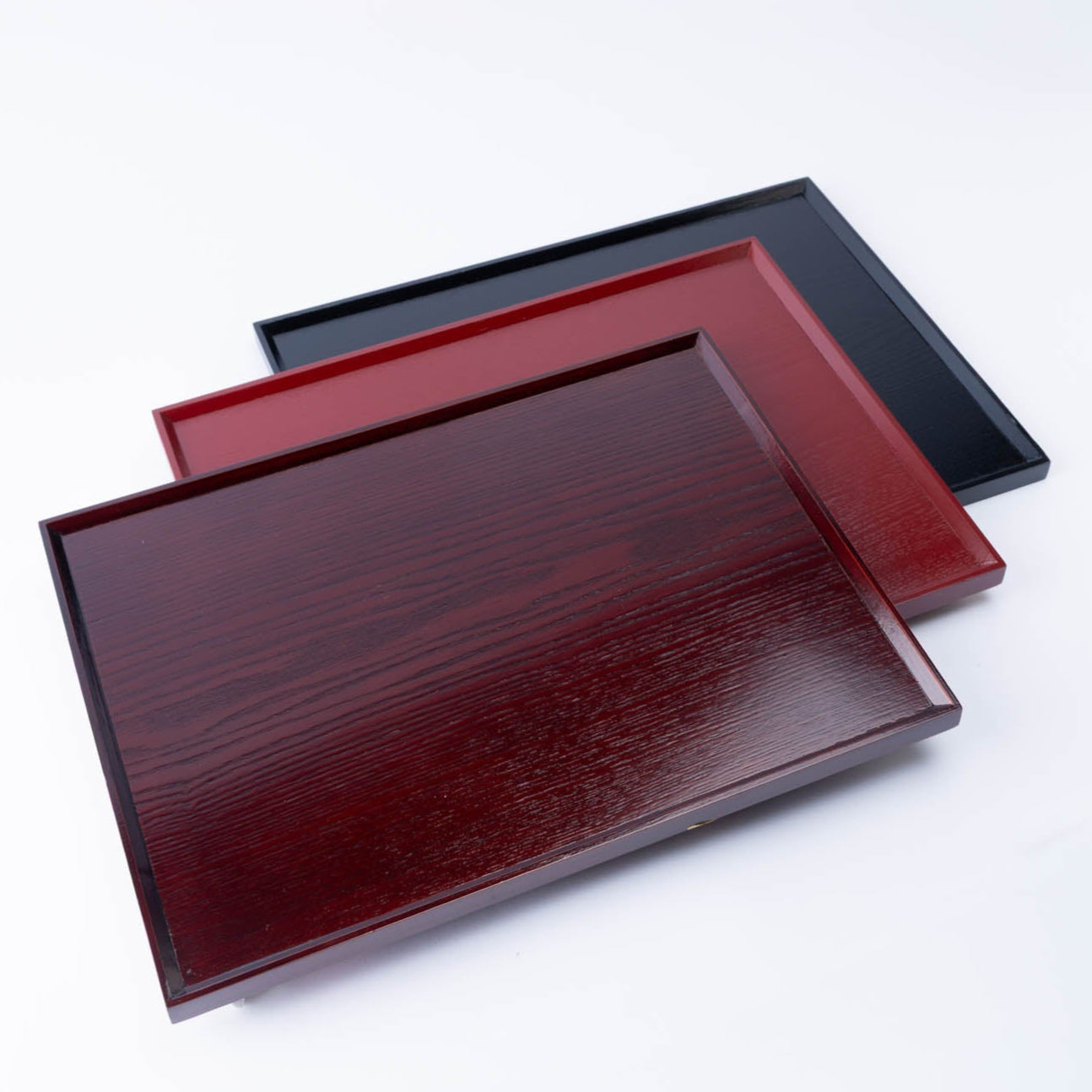

Once the base is prepared, it is time for the lacquerer, or nuri-shi, to apply the Japanese lacquer. Lacquer is applied with a brush, a process that requires control of the humidity to allow the lacquer to harden and full mental concentration to prevent dust and dirt from sticking to the surface.

One of the techniques, fuki-urushi, involves applying lacquer to best display the beauty of the wood grain. The process of applying and wiping transparent lacquer is repeated many times to allow the lacquer to soak into the wood grain.

Maki-e Artists

Beautiful maki-e is the work of a specialized craftsperson, the maki-e shi. First, a rough sketch is copied onto the surface of the finished Japanese lacquerware and patterns and letters are drawn using lacquer. Then, while the lacquer is still hardening, colored or metal powders such as gold and silver are sprinkled on the surface. After that, it is coated with clear Japanese lacquer and polished carefully.

There are a variety of maki-e techniques in Japan. Yamanaka lacquerware is famous for its taka maki-e technique, which gives a three-dimensional effect.

Photos by Yamanaka Japan

Makers

Related posts

Filters