Naruko Kokeshi Dolls

Naruko kokeshi dolls originated in the late Edo period (1603 CE–1867 CE) when wooden bowl and tray makers crafted them to provide amusement for their own kids as well as those of their neighbors. As the years progressed, they were sold as souvenirs, paving the way for adults to make collecting and appreciating these dolls a hobby.

Naruko kokeshi dolls were designated as a national traditional handicraft by the Japanese government in 1981, when the traditional kokeshi dolls of Miyagi Prefecture were grouped together as "Miyagi traditional kokeshi dolls."

Naruko kokeshi dolls have a cute, innocent expression, and their tied bangs and red hair ornaments are very charming. In the late Edo period they were made as children's toys, but they gradually became popular with a wide range of people as decorative figurines. The number of young fans has been increasing in recent years thanks to the dolls’ sense of nostalgia and comfort.

The most distinctive feature of the doll is the squeaking sound it makes when the head is turned. The technique of fitting the head into the hole in the body while turning the lathe is something only a skilled kokeshi craftsperson can do. The design features two or three chrysanthemums seen from the side, painted on top of each other on the body. Another well-known pattern is the hishikiku, or rhombus chrysanthemum, a glossy bloom depicted as seen from directly above. These patterns are often expressed with attention to the flowers’ forms, either alone or in combination. While chrysanthemums are the most common, patterns of maples, peonies, and irises are also found.

The wood surface feels comfortable to hold and pleasant to the touch. Their classical forms reveal the talents of the artisans who lived in the mountains decades ago. Graceful yet rustic, these dolls are a testament to both the beauty of nature and the skill of the craftsmen.

Kokeshi dolls vary in size, but small ones can be carried around or displayed on a shelf, while large ones, which are over one meter in length, are often placed on the floor. Each doll has a different face and pattern, so they are fun to collect!

1. Drying the logs

The most commonly used logs for kokeshi doll making are mizuki (dogwood), which has a fine white bark, and maple, which develops a beautiful luster over time. The raw wood for kokeshi dolls is harvested in the fall when the wood does not contain much moisture. The bark is peeled off and the wood is left to dry naturally for six months to one year.

2. Cutting

The logs are cut to the size of kokeshi dolls and roughly shaved into cylindrical shapes to be ready to set on a woodworking lathe. The head and body of the dolls are made separately.

3. Woodworking

The wood is then attached to the axis of a woodworking lathe, and while rotating, a plane is applied to the wood to carve it into the desired shape.

4. Painting

The face and body are painted using ink and red, green, and other paints.The maker’s name is added to the bottom of the body.

5. Waxing

The head and body are each placed on the lathe. Wax is poured over both parts, fully melted over the entire body to prevent unevenness, and polished with a cloth to bring out the luster.

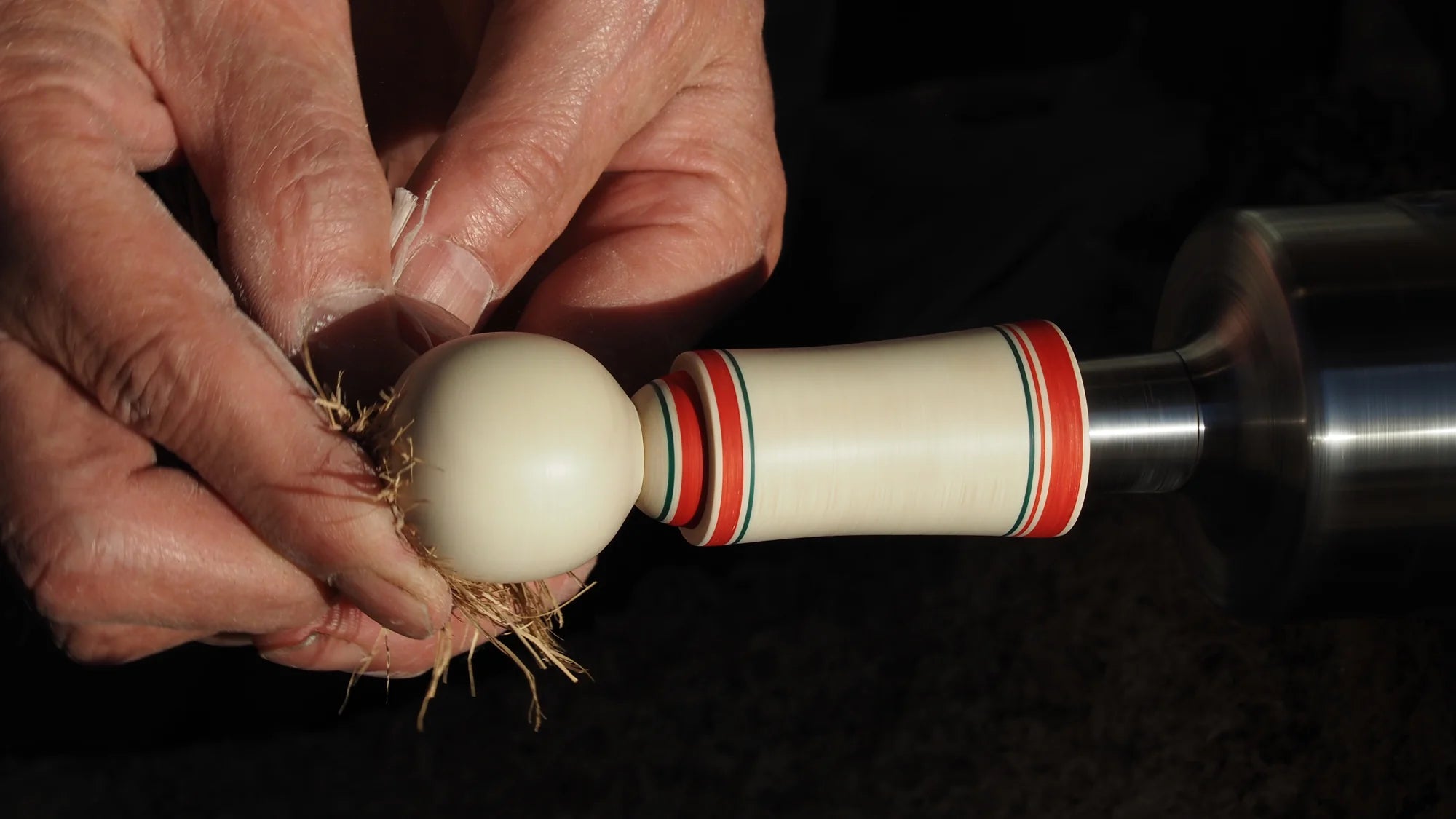

6. Insert the head

The head is inserted firmly into the body. Care is taken to perfectly match up the body pattern and the face.

Makers

Filters