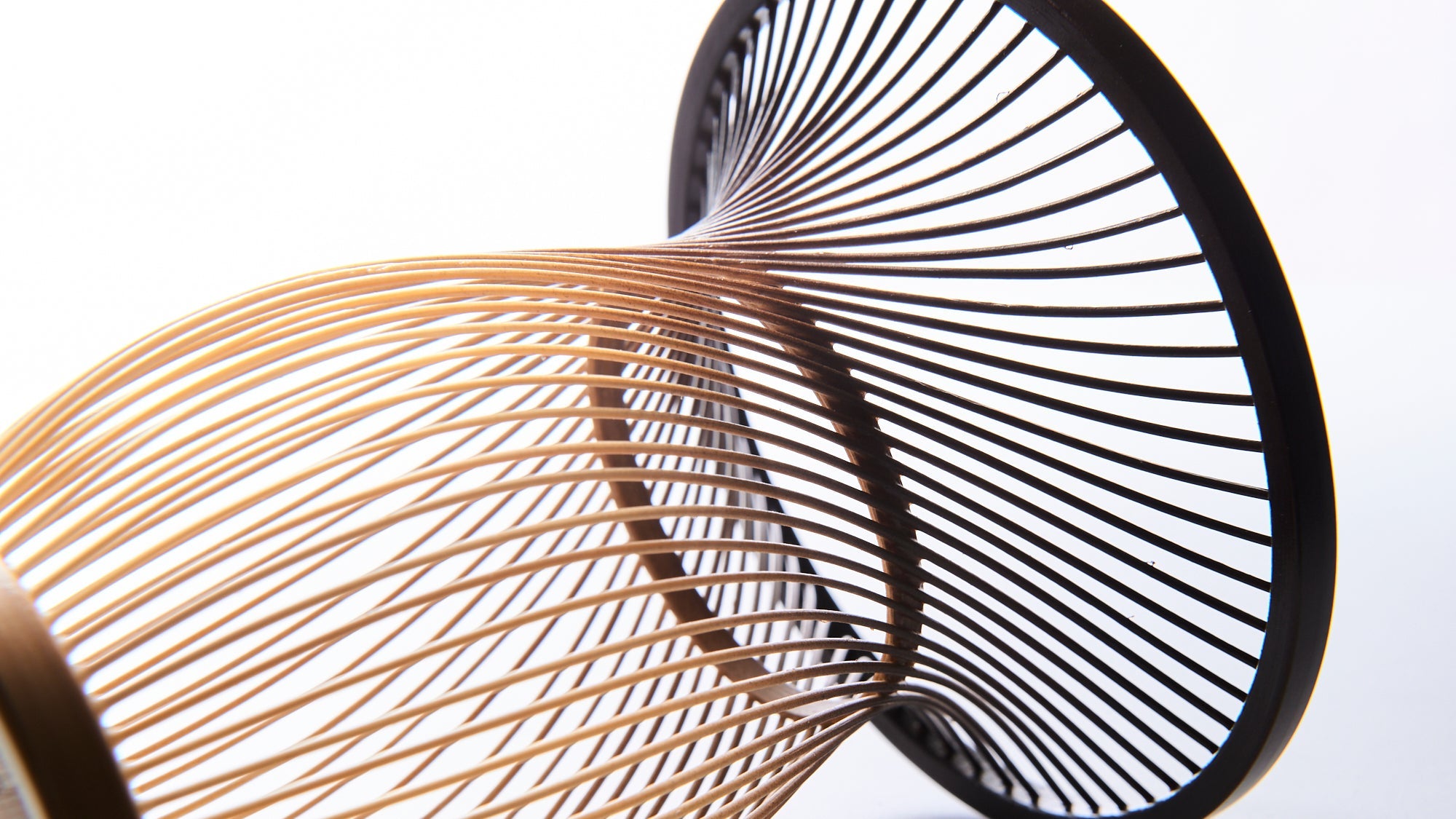

Delicate and Graceful Japanese Bamboo Artwork

Suruga Bamboo Basketry

Suruga Bamboo Basketry is a traditional Japanese craft with a legacy spanning over 400 years, originating from the vicinity of Shizuoka City, Shizuoka Prefecture. Recognized as a national traditional craft in 1976, its inception is steeped in legend, tracing back to a court aristocrat's quest for elegant baskets. Over time, it evolved to produce bait containers used in falconry, commissioned by Shogun Tokugawa Ieyasu, highlighting its aesthetic refinement tied to the leisure pursuits of nobility.

Suruga Bamboo Basketry is characterized by the fact that it uses a numbers of fine bamboo strips, as indicated by the name sensuji (meaning one thousand lines). Unlike other Japanese bamboo crafts, Suruga Bamboo Basketry uses thin, round bamboo strips. It is said that the reason for taking the time and effort to make and use rounded bamboo strips one by one is out of concern for not damaging the feathers of the birds and insect cages that are one of their signature products.

Bamboo basketry look delicate at first glance, but craftsmen go through many processes to take advantage of the strength and flexibility characteristics of bamboo, making it very durable and long-lasting. The handiwork of craftsmen who carry on the tradition breathes new life into the bamboo, which is then passed on to the next generation by the user. The delicate and graceful design, along with the natural texture of the bamboo as it turns into an amber color, will ensure long-lasting use with love and affection.

Suruga bamboo basketry (called suruga take sesuji zaiku in Japanese) is produced in the city of Shizuoka, Shizuoka prefecture. High-quality bamboo has grown wild in the basin of the upper reaches of the Abe River in Shizuoka since ancient times. According to records, a woven bamboo pillow was made in the early Edo period (1603 CE–1868 CE), and was used in the Edo Castle.

It is said that the origin of Suruga Bamboo Basketry, which is still practiced today, began when a samurai from the Okazaki domain, who was on a journey, taught the delicate bamboo weaving technique using a bamboo strip to the craftsmen. Using this technique, they began to make confectionery containers and insect baskets, which were sold to travelers on their way up and down the Tokaido Highway as handicrafts.

Photo courtesy of Shizuoka Bamboo-craft Corporative Association

Trimming to Size

To remove scratches and dirt from the surface of the bamboo, shave the bamboo bark and split the bamboo into strips about 1 cm (0.4 in) wide with a nata, a sturdy broad-bladed knife. The inner soft part of the bamboo is cut off, and the part close to the outer skin, which is stronger, is used for the bamboo strips.

Kowari (slitting)

The bamboo is then split into stripes without breaking the bamboo fibers. The bamboo is bent right and left by hand until split at the end. This is a unique technique of Suruga bamboo basketry that can only be done with Japanese bamboo, which is very flexible and strong.

Cutting and rounding strips

A small knife is used to cut a fine slit in the bamboo, which is then split by hand as if pushed in. The ends are sharpened to a thin point. The shaved bamboo is passed through a hole in a steel plate to make a round bamboo strips. The size of the hole varies from thick to thin, and the bamboo is passed through the narrower hole gradually, in the order of rough, medium, and finish, to produce a beautiful rounded bamboo strips.

Bending

Bamboo strips are sometimes used straight, but they can also be bent to create various shapes of bamboo crafts. Twenty to thirty bamboo strips at a time are bent using a hot electric iron. Careful work is necessary because uneven bending will affect the quality of the finished product.

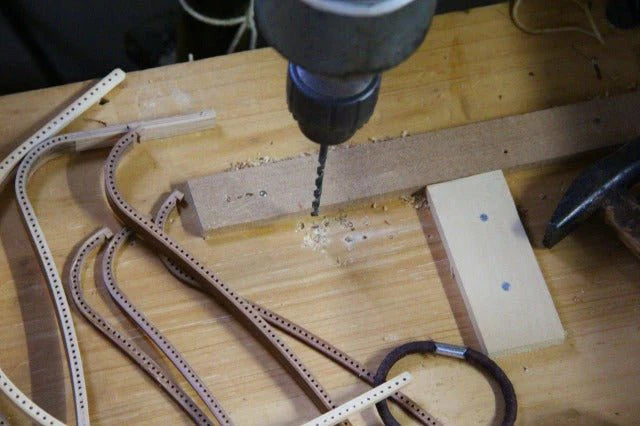

Drilling

This is a very nerve-wracking process, and the size of the holes varies millimeter by millimeter depending on the thickness of the strips. In addition to drilling holes regularly, the angle of each hole is also slightly changed to match the angle at which the strip is inserted. This is an important process that greatly affects the assembly process.

Assemble

The work is assembled by inserting round bamboo strips into the holes drilled in the rings. If the bending of the bamboo strips and drilling of the rings are done well, it is possible to form beautiful shapes. The bamboo strips are carefully inserted one by one to form the shape of the work. The rings are then turned on a wood lathe and polished to a smooth finish.

Photo courtesy of Shizuoka Bamboo-craft Corporative Association

Makers

Related posts

Filters