Utsutsu Kiln

Utsutsu Kiln was opened in 2000 by woman ceramic artist Inazumi Kakoku. Inazumi uses Kutani ware techniques as the base for her work but does not limit herself, instead using her ingenuity to create pieces with a texture unique to her. Her delicate touch, gorgeous colors, and patterns based on the theme of dreams and fantasy show her warm personality and free spirit.

Filters

Wind's Path Deep Dinner Plate 10.2 in

Sale price$275.00 USD

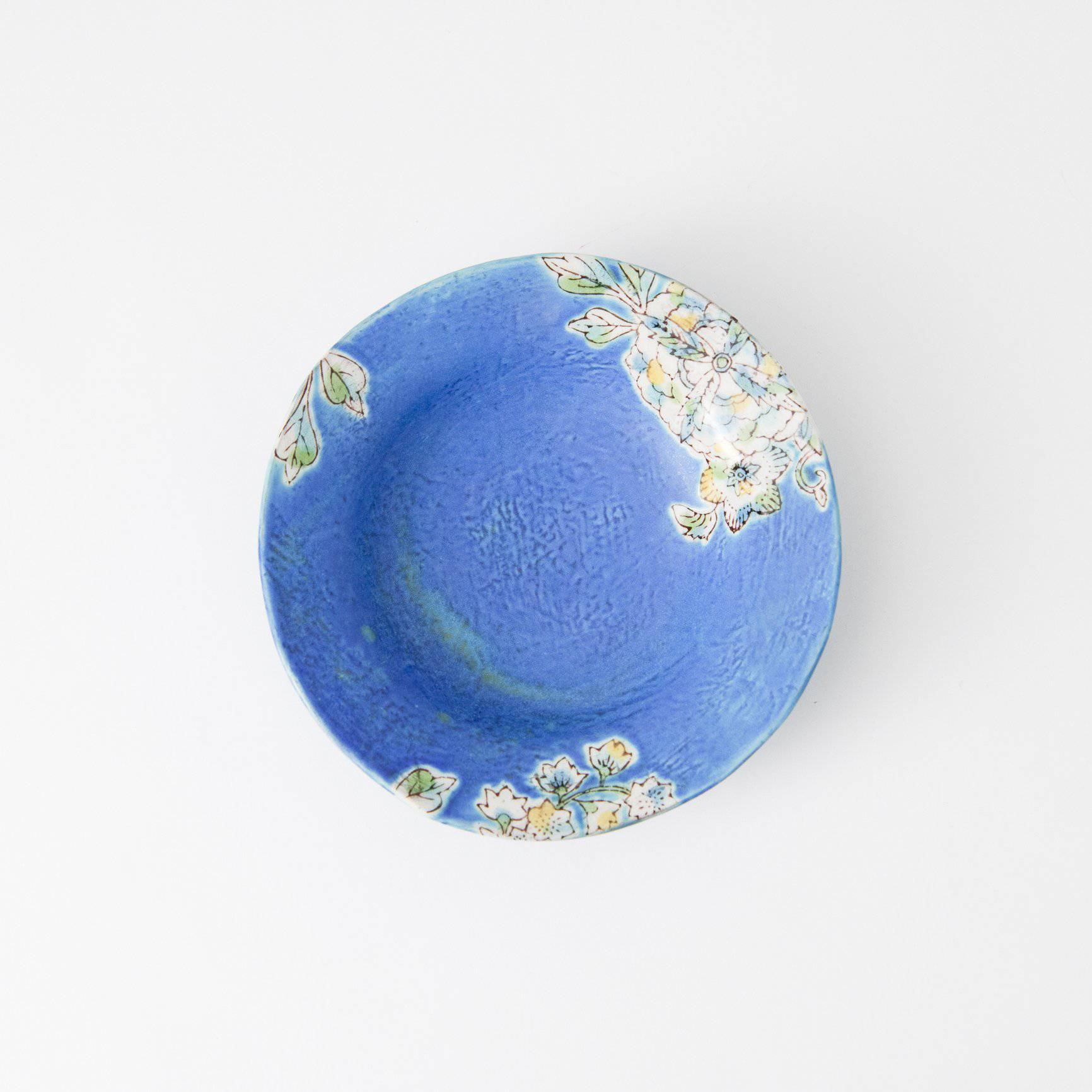

Wind's Path Kobachi Small Bowl

Sale price$116.00 USD

Wind's Path Sauce Plate

Sale price$52.00 USD

Wind's Path Mug

Sale price$135.00 USD

Wind's Path Deep Dinner Plate 8.7 in

Sale price$170.00 USD